N.W.Geeson I.Eng. M.I.R.T.E M.S.O.E (VER 2.JAN 2010)

History, background and the problems arising

The wheel bearings of the S Type & Silver Cloud chassis range differed from the earlier post-war cars in being fitted with grease seals and seal carriers on each side of the bearings. These seal carriers not only support the oil seal “O” ring in an external groove but they also have an Acme scroll grease return thread on the inner diameter. Unfortunately from a spare parts point of view the seal carriers have “handed Acme” threads, that is, left and right hand threading. These seal carriers can be removed easily if they are left in place whilst the bearing is pressed off the half shaft. If,on the other hand, they are removed to regrease the bearings, which was their original intention, they are liable to break unless the correct removal tool is used. In any event they are extremely expensive, as are the bearings.

Originally this seal design was to be incorporated on all cars from C series MkVI onwards retrospectively on spare parts, and introduced on S types from new. The scheme was drawn up as (Park Lees) PL 7072 in February 1952. To retrospectively fit this design to early cars would have required an alteration to the existing spacer that fits onto the half shaft before the bearing, the addition of the spacers and finally slight alteration to the old bearing. In the end there was no retrospective action.

The original wheel bearings had a special inbuilt end float and the service manual warned against renewing the bearings just because the end float was present. Unfortunately this bearing end float allows the half shaft splines to end float in the splined bevel wheels. Readers who are in the automotive engineering field will realise that splined shafts resist end float when under driving conditions, but when the splines do slide, they wear the half shaft splines. When the shafts do not slide, they transfer the end load directly onto the axle bevel gear thrust washers.

The rear wheel bearings are about the last components that need renewal on these cars, long after the engines have worn out, however after some 50 years the bearing grease is almost non- existent and what remains is not a good lubricant. Even attempting to re-grease the bearing provides no guarantees as the tracks, balls and cages are worn and they fail with little or no warning. Re-greasing a bearing after a considerable period of time, without doubt, will appear to make the bearing revolve smoother. It does not however replace metal that has worn off the bearings and which is captured in its granulated state within the sealed bearing. Metal which, given time, will guarantee a collapsed bearing but no guarantee is given as to whether the affected car stays on its four wheels. The only decision you have to make is whether your life and others are worth the cost of the bearings.

Persistent running with slack and partially failed rear wheel bearings will eventually cause the bearing to turn on the half shaft and within the bearing housing. A faulty rear wheel bearing is one cause of failure of the main axle bearings and in fact scrapping, or the need to insert the main axle case and the inner differential gear case. Turning the subject on its head, the failure of the axle side bearings will, and does, fail the rear wheel bearings. Each set of bearings support the half shaft at either end, indirectly through a bevel gear at the inner end, so a complete bearing failure at one end affects the other end. The initial failure of the wheel bearing is often followed by a clicking noise, which sometimes disappears temporarily when the car is reversed. Unless the bearings are really badly worn it can be difficult to detect actual wear when the car is jacked up with the load relieved from the bearing and the wheels are spun. In fact it is much easier to detect the wear when the wheel is removed as any imperfect movement of the bearing is hidden by the heavy flywheel effect of the road wheel. Once the wheel is removed it becomes necessary to have a good ear and light touch, rotating the hub back and forth feeling and listening for noise and roughness. Along with this back and forth movement the half shaft needs continually indexing around to cover the full 360 degrees of the bearing.

As the tooling and spares are not easily obtainable when out on the road, it is advisable to renew the rear wheel bearings unless the owner knows for sure that the bearings have been changed. Failing that, at least check the rear wheel bearings most thoroughly for any signs of wear.

I can almost hear the average enthusiast saying that he / she is bound to hear the trouble arising before disaster strikes. I am afraid that does not bear out on the facts. As I mentioned previously, initial failure is often fairly quick. At 50 / 60 mph the rest is history!

Conversion to modified bearing RG8104P

The conversion mentioned below is suitable for use with all S1, S2, S3 & Silver Cloud I, II, III (and their Continental derivatives) half shafts.

The original rear wheel bearings are still available but very expensive. This original bearing is capable of taking side thrust loads and any replacement type must be a thrust bearing, as a normal roller bearing will quickly fail. Erring on the side of good engineering principles it makes sense, and has advantages, to fit a dual row bearing. |

|

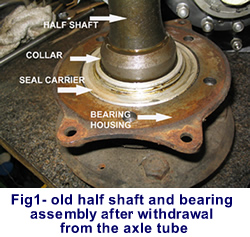

The various workshop manuals describe the removal of the half shaft assemblies, which are removed complete with bearings and bearing housings. Fig 1 shows a very old unit to illustrate what the assembly looks like after its removal from the axle.

Fig 2, Fig 3 and Fig 4 show comparisons of the original and new bearings in various states of dress.

Note in Fig 2 how the two original side oil seals and carriers make up the width of the old assembly to fit in the wheel bearing housing.

This conversion uses a new neoprene sealed type bearing. This particular heavy bearing was chosen because it has far greater load-carrying capacity than the original bearing and the wider outer track enables the wheel loading to be evenly spread along the wheel bearing housing. In addition the width of the bearing is the same as the housing depth and enables a straightforward replacement when the original grease seal carriers are discarded.

The services of a machine shop will usually be needed to mount the half shafts in a lathe and machine away the old bearing retaining collar. Access to a press bed of at least 25 ton capacity is required to remove the old bearing and then press into place the new bearing and retaining collar. The highest load will normally be experienced when pressing off the old bearing which tend to come loose with a bang around 16 ton rather than a steady push. Expect that after fitting all the parts a final load of 20 tons should be applied.

Due to the high loads that the component parts will experience it is vital that the bearing housing is supported well to avoid damage. It is of no use changing the bearings or even an axle assembly if the bearing housing has been warped during the procedure. We recommend the use of specialist tools to hold the housing.

| Next Page >> |